Abstract:

A perfect glass bottle to be produced and delivered to the customers needs six steps.The six steps are selection of raw material、melting of raw material、shape forming、 annealing、quality testing and packing.Now,I will carefully introduce how is a glass bottle produced from these six aspects.

Step 1:Selection of raw material

Most of the raw materials used to make glass bottles are sand, soda ash and limestone. Broken glass is added to the mixture. Broken glass is broken glass, whether waste from the manufacturing process or from recycling centers. For every ton of glass recycled, 1,300 pounds of sand, 410 pounds of soda ash and 380 pounds of limestone are saved. This will save manufacturing costs, save costs and energy, and enable customers to get economical prices on our products.

Step 2:Melting of raw material

The raw material and broken glass are continuously melted at a high temperature, around 1650°C, and the furnace runs 24 hours a day, with the raw material mixture forming molten glass for about 24 hours. Molten glass passes through the feed channel, and then at the end of the feed channel, the glass flow is cut into blocks according to weight, and the temperature is precisely set.

Step 3:Shape forming

There are two ways to shape a glass bottle-Pressing molding or blowing molding,both in an IS machine.

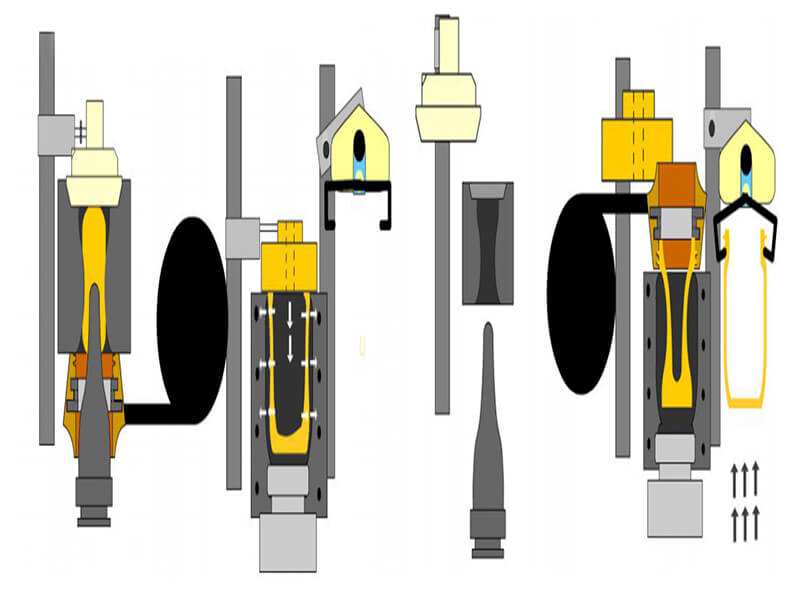

Pressing Molding

When the cut material drops down and presses the material into a blank die with a metal plunger, where it expects the shape of the die, which is then called a blank. Next, the billet is moved into the final mold and blown into the mold for final measurement. This process is usually used for wide-mouthed glass bottles, but can also be used to produce thin-necked glass bottles.

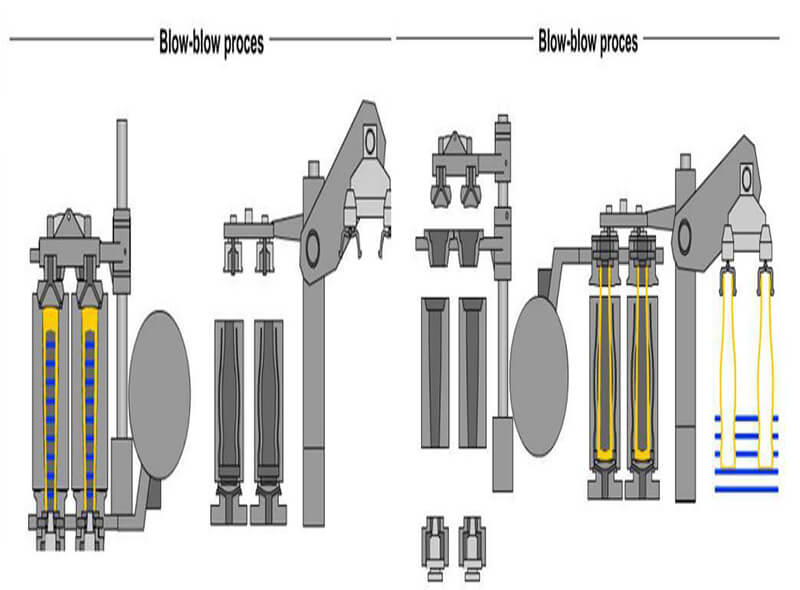

Blowing Molding

When the cut material drops down, and in the blowing molding, the material drops are compressed into the blank mold, and the compressed air is used to push the material drops into place, called the blank, and move to the final mold and blow molding again to form the inside of the frame glass bottle. Glass bottles (narrow containers) with different neck thicknesses can be made by blowing arrangement.

Step 4:Annealing

Regardless of the process, blown glass containers are usually surface coated after forming. To make the bottles and jars more scratch-resistant while they are still hot, the bottles are taken to a annealing furnace for a hot end finish. In the annealing furnace, their temperature was first restored to about 815 °C, and then decreased gradually to below 480°C. This process takes about 2 hours. This reheating and slow cooling removes the pressure in the vessel and enhances the robustness of the naturally formed glass vessel.Otherwise, the glass will break easily.

Step 5:Quality Testing

Glass bottles and jars are usually treated with a cold end surface coating to reduce the temperature of the terrarium to about 100°C prior to inspection. After leaving the cold treatment end of the annealing furnace, in order to ensure the quality of the product, we use Led beam technology (Led detection), Camara detection machine, comprehensive detection machine to detect the invisible faults. These include, but are not limited to: sealing surface detection, dimensional analysis, wall thickness detection, damage detection, edge bottom scanning, wall scanning. Any bottles that do not meet the standards will be automatically removed, and these removed bottles will be re-melted as raw materials for reuse.Automatic detection will ensure stable quality for our customers.

Step 6:Packing

Bottle packing method will be subject to customer requirements. We usually pack in the following two ways-pallet packing(suitable for large orders and sea transportation) and carton packing(suitable for express delivery)