How To Measure Neck Finish?

It is important when considering packaging to have a clear understanding of neck finish dimensions. When selecting a closure for a container there are several measurements needed to ensure a secure and sealed fit.

It is critical to find suitable lids and neck finish for your packaging bottles. Our engineer of Panyue will guide you here to complete common neck finish and bottle lid selection.

First we’d better know what’s the neck finish.

What Is Neck Finish?

Neck Finishes are the screw-threaded parts of the bottles that hold the cap or closure in place. A bottle must have a proper neck finish to match the corresponding cap.

The first number refers to the overall neck diameter including the threads outside in millimeter.

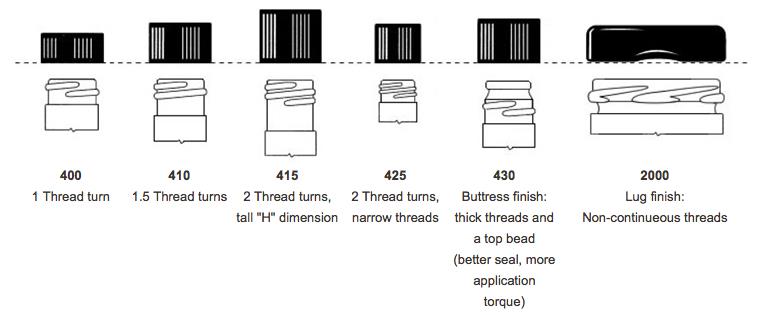

The second number refers to the height and thread style of neck finish, which ranged from 300 to 2060, but most commonly used thread styles are 400, 410, 415 in glass bottles industry, also is the most 3 types that our exported glass bottles used.

Continuous threaded cap sizes are expressed as two reference numbers, such as 24-400,18-410, 20-415.

Let’s quickly look on the thread counts of those 3 type thread styles.

How To Measure Neck Finishes?

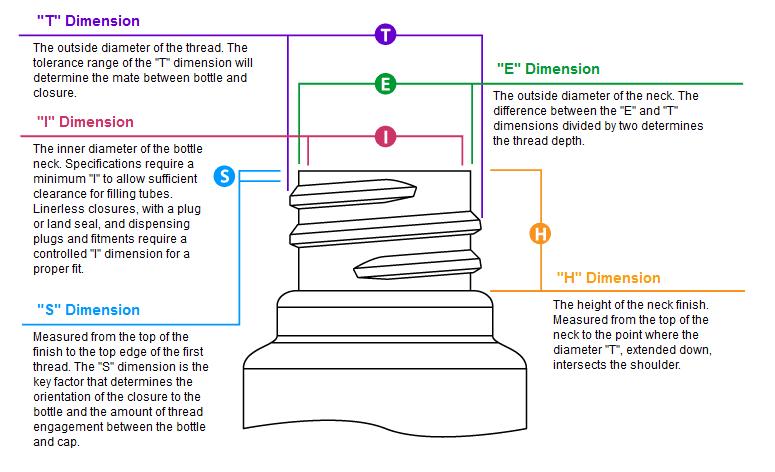

Let’s checkout these parameters below first:

"T"is the overall neck diameter in millimeter including the threads outside, such as 24in 24-400.

"E"is also the neck diameter, but measured with the threads depth excluded if compared to T diameter.

"I"is the inner diameter of the neck.

"S"is measured from the top edge of the mouth and stops when threading begins.

"H"is the height of the neck finish, which measured from the top of the mouth to the bottom of the closure rests.

Therefore, thread depth is also available now, which is the result from (E-T)/2.

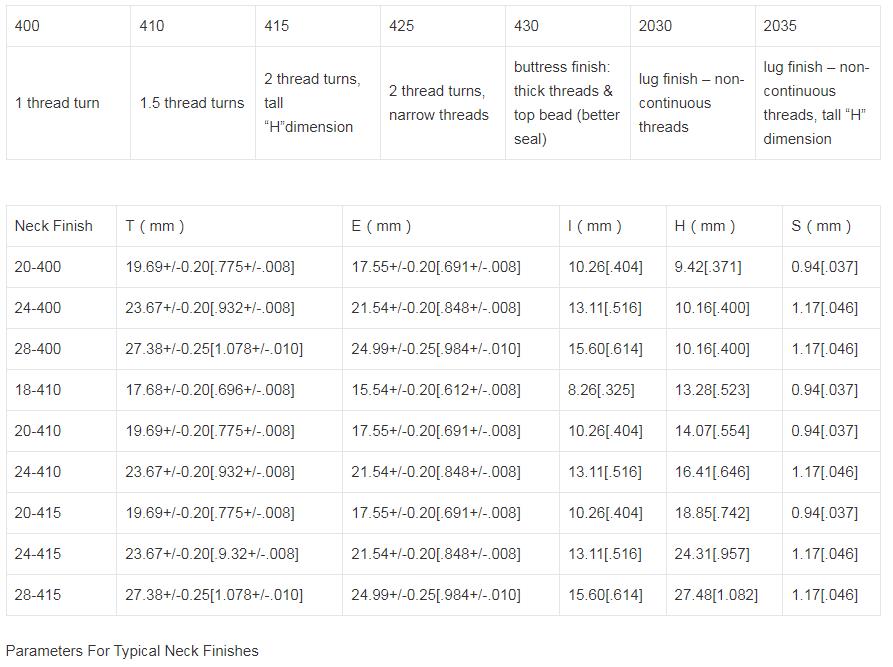

Parameters For Typical Neck Finishes

Method Of Measuring Neck Finishes

Step1:

To find a cap’s diameter, measure from one side of the inner wall to the opposite side. Calculate a bottle’s neck finish by measuring the diameter of the outermost threads. The resulting millimeter measurement will be the “T” dimension.

Step2:

Then, see how many times the threads pass one another to determine the finish.

(ex. 20 mm “T” dimension with 1.5 thread turns = 20/410 neck finish)