Cosmetic glass packaging processing technology

1. Colouring process

Electrified aluminum: aluminum exterior,on a layer of film wrapped around the inner plastic layer.

Electroplating: the effect comes out bright compared to painting.

Spraying: The colour is dark and matte compared to electroplating

Sprayed on the outside of the inner bottle:the bottle is sprayed on the outside of the inner bottle,with a clear gap between it and the outer bottle and a small sprayed area when viewed from the side.

Spraying on the inside of the outer bottle:the spraying is done on the inside if the outer bottle,the area looks larger from the outside, the vertical plane looks smaller and there is no gap with the inner bottle.

Brushed gold and silver:it is actually a film,and the gaps can be found on the bottle upon closer inspection.

Secondary oxidation:This is a secondary oxidation on the original oxidation layer,so that the light surface is covered with a dark matte surface pattern or the dark matte surface appears as a light surface pattern,mostly used for the production of logos.

Injection moulding colours:This is a relatively inexpensive process in which colour powder is added to the raw material when the product is injected,or bead powder can be added.

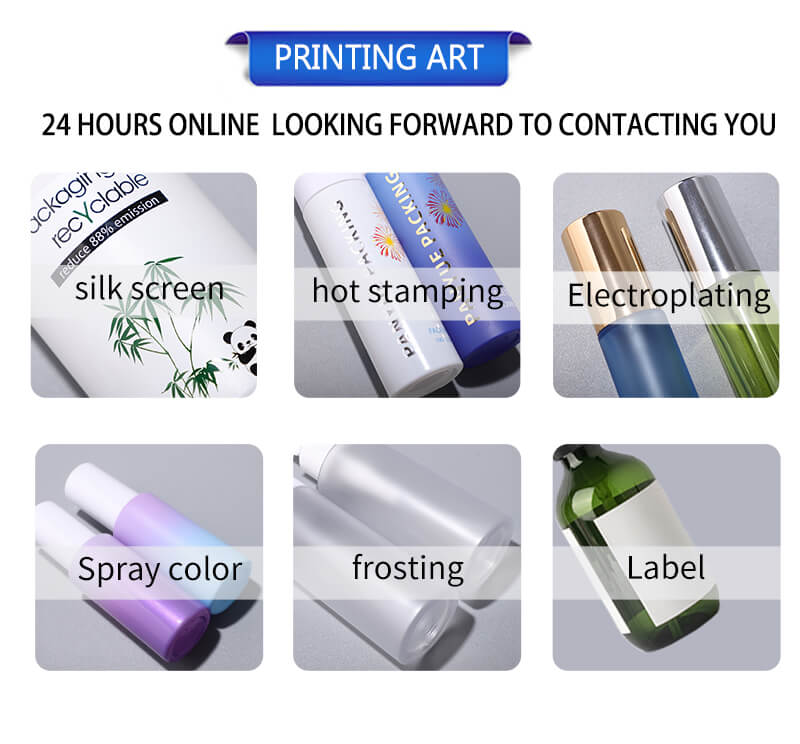

2.Printing process

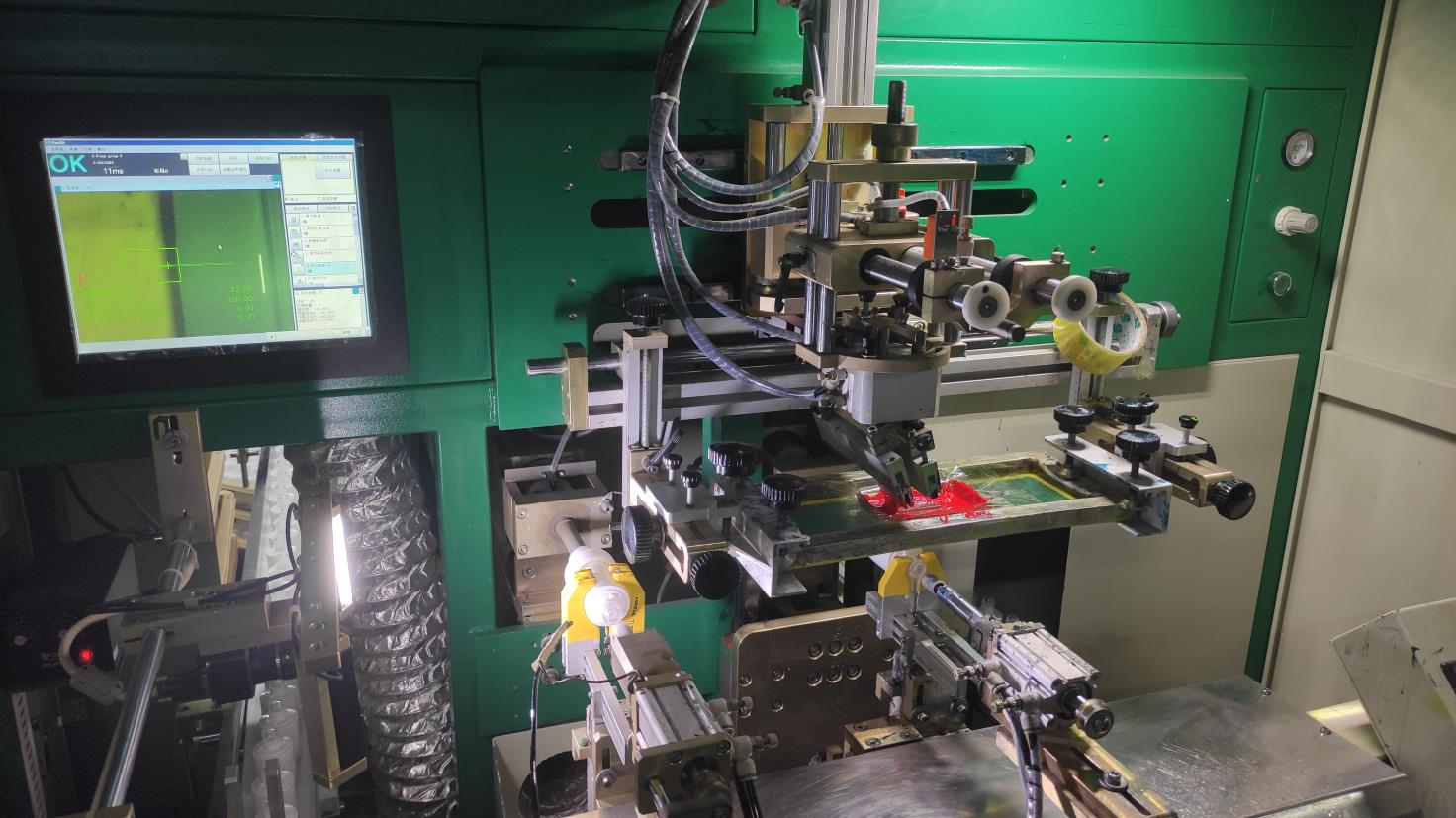

Screen printing:one is high temperature ink screen printing,it's characteristics are not easy to decolourisation, the colour is more dull and dull,purple toning is more difficult to produce results,the other is low temperature ink screen printing, the colour is more colorful, the requirements of the ink is higher,other wise it is easy to fall off, and in the bottle disinfection to pay attention to.

Stamping: is a thin layer of paper stamping on the top.so there is no screen printing of the bumpy feeling.Stamping is best not directly on the PE and PP materials,you need to heat transfer before stamping or have good stamping paper can also be directly stamped.

Water transfer printing: is placed in water for the irregular printing process, the printed pattern is not consistent and more expensive.

Heat transfer printing: Heat transfer printing is mostly used for large quantities,printing complex products,belong to the surface attached to a layer of film,the prices is expensive.

Offset printing: mostly used for aluminum-plastic hose and all-plastic hose,offset printing will have a base colour through out,sometimes attached to the surface of the hose a bright film or matte film.

In summary,cosmetic glass packaging is exciting,is a good choice for packaging cosmetic.GUANGZHOU PANYUE PACKING.CO.,LTD.produces and sells high quality cosmetic glass packaging and offers customization services.If you needed you can visit GUANGZHOU PANYUE PACKING.CO.,LTD.