In daily cleaning products such as shampoo, shower gel and conditioner, PET (polyethylene terephthalate) bottles stand out from many plastic products and become the main choice in the market due to their excellent transparency, outstanding physical properties, mature recycling system and flexible processing technology. This time we will introduce PET bottles as a plastic container from three aspects: functional advantages, processing technology and structural design innovation.

1. Functional advantages of PET bottles

PET bottles have several key advantages in the packaging of cleaning products:

Lightweight and shatterproof: PET is durable and not easy to break even if it falls in a humid environment such as the bathroom, ensuring safe use. Compared with glass bottles, it greatly reduces transportation costs and carbon dioxide emissions. It can effectively resist impact during transportation, storage and use, and reduce the risk of breakage and leakage.

High transparency: PET bottles are clear and bright with good gloss, which can intuitively display the texture and color of the product and enhance the product's appeal on the shelf.

Strong chemical resistance: Suitable for shampoos and shower gels containing surfactants, essential oils and other ingredients.

Environmentally friendly and recyclable: In line with the trend of sustainable packaging, it can be recycled to reduce the impact on the environment.

Strong stability: The bottle is not easy to deform, ensuring that the appearance of the bottle remains consistent. PET bottles can be lightweight while ensuring strength, and also bring convenience and comfortable soft touch to consumers for daily holding and squeezing. Effectively resist collisions during transportation, storage and use, and reduce the risk of damage and leakage.

2. Manufacturing process of PET bottles

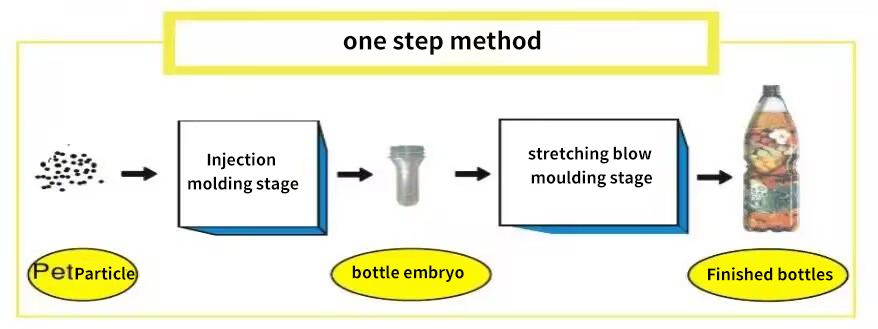

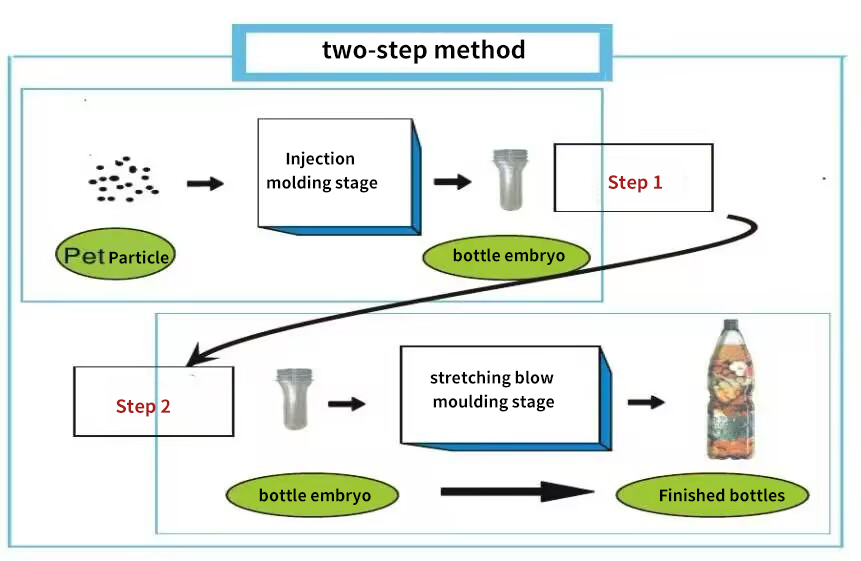

There are two main processes for forming PET bottles: one-step and two-step. The choice depends on factors such as cost, efficiency, and order size.

Single-Stage: The three core processes of Injection Molding -> Heating and Temperature Control -> Stretch Blow Molding are completed continuously on the same dedicated equipment.

Advantages: compact process, high degree of automation, fast production speed, high energy utilization efficiency, and reduced risk of bottle embryo contamination. Disadvantages: high equipment investment cost and relatively low flexibility (suitable for large quantities of single bottle types). Applicable to: large-scale production of main product packaging of large-scale cleaning brands.

Two-Stage: First, the PET raw material is injection molded into a preform, and the preform is stored or transported after cooling. When necessary, the preform is reheated and stretch blow molded.

Advantages: Relatively low equipment investment (can be invested in steps), high flexibility (different preforms can be switched to produce different bottles at any time according to demand), convenient centralized production of preforms and decentralized blowing (such as close to the filling plant). Disadvantages: The overall energy consumption is slightly higher than the one-step method, the production cycle is slightly longer, and there are management costs for the storage and transportation of preforms. Applicable: Scenarios where small and medium-sized batches are produced, multiple varieties of bottles, and the supply chain needs to be decentralized.

The PET raw material is heated and injected into the mold to obtain a preformed bottle embryo. The bottle embryo is the core intermediate in the manufacture of PET bottles. Its design (weight, wall thickness distribution, neck size) directly determines the performance (such as strength, capacity, hardness) and appearance of the final bottle. The bottleneck size is determined during the injection molding stage and no changes are made in subsequent operations.

After heating the preform to the appropriate temperature, it is stretched longitudinally, and high-pressure air is injected into the preform to expand it laterally and cling to the inner wall of the mold. After injection molding, the PET bottle is cooled, taken out, and enters the inspection and packaging stage. Stretch blow molding are key steps to give the bottle its final shape and performance.

Inner wall hydrophobic coating: To solve the problem of sticky cleaning products (such as lotions and conditioners) hanging on the wall, an inorganic silica hydrophobic coating can be applied to the inner wall of the PET bottle.

External surface treatment: such as matte frosting (to enhance texture), anti-scratch coating, etc.

3. Structural design features of PET bottles

The structure of PET bottles is usually personalized according to the use function and filling requirements.

Bottle mouth thread design: adapt to pump head, push cap or flip cap to improve sealing and user experience.

Thickness and thinness of bottle body: reasonably control the wall thickness distribution, enhance pressure resistance and appearance beauty.

Anti-slip bottle bottom: improve placement stability through thickening or anti-slip texture treatment.

Supports multiple printing methods: such as silk screen printing, thermal transfer, label attachment, etc., to meet the needs of personalized brand customization.

Diversified bottle design: unique shapes (such as curves, edges, and bionic forms) are designed through precision molds.

Large-capacity handle design: snap-in handles and adhesive handles are important for improving portability. The bottle body has no seams and is 100% recyclable.

Labels and decorations: In-mold labeling, wash labels, and screen printing are all appearance decorations that are friendly to recycling.

In today's rapidly developing cleaning industry, PET bottles have an excellent balance of function, cost, beauty and sustainability.

As a professional cleaning PET bottle supplier, we provide one-stop services from bottle design, mold development to OEM customization to meet your diverse needs from standard models to high-end customization.